Rethink Concrete Roof Sequencing - Build Sooner with SlopeShield Plus SA

SlopeShield Plus SA gives contractors the flexibility they need with today's demanding schedules and labor-challenged market.

SlopeShield Plus SA gives contractors the flexibility they need with today's demanding schedules and labor-challenged market.

Benefits:

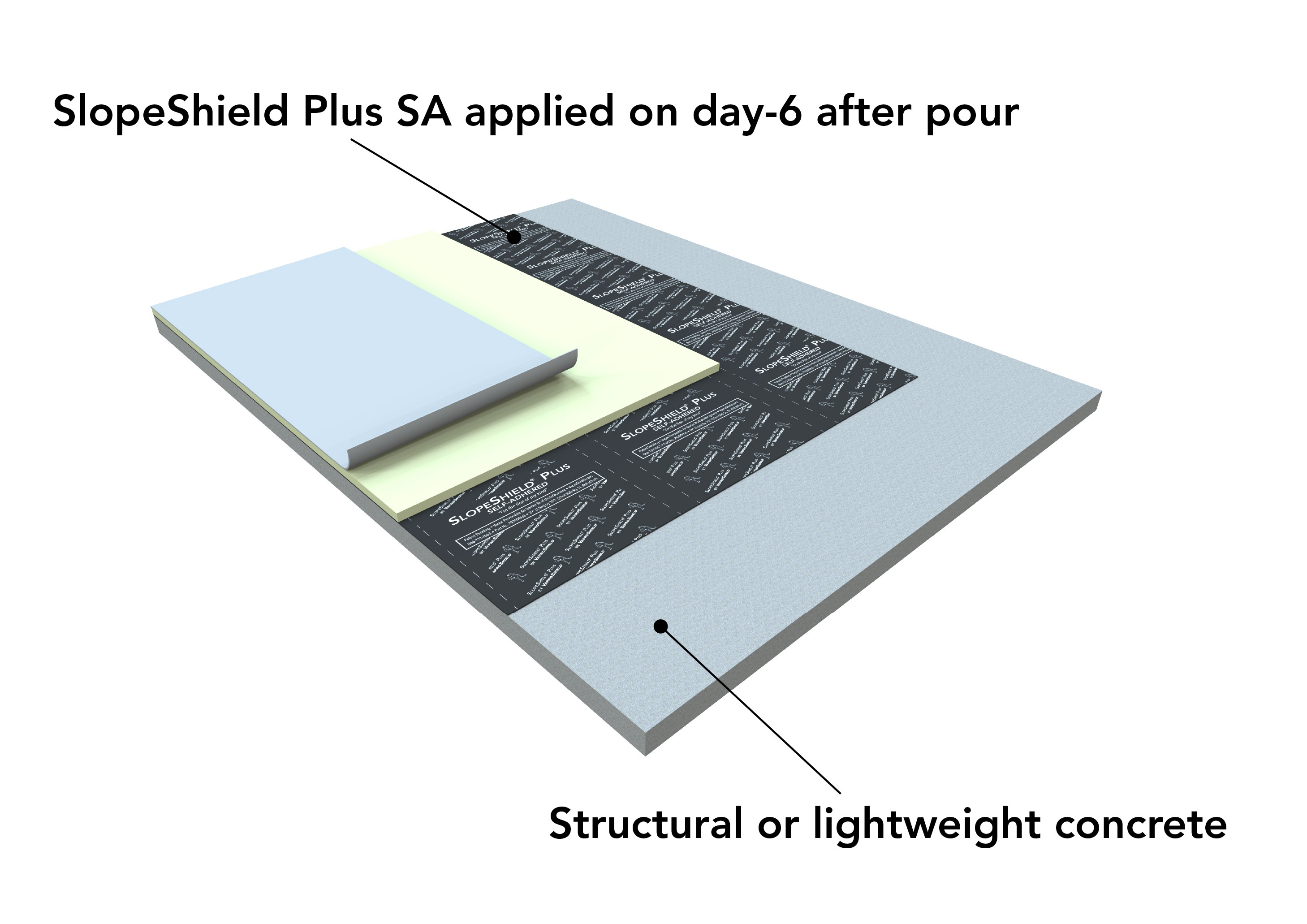

- Apply as early as day-6 after a concrete pour or directly to damp concrete during reroofing

- Prevents weather-related rewetting enabling early dry-in

- Allows interior trades to safely begin BEFORE completing 28-35 day cure cycle

- Eliminates curing calendar resets avoiding costly setbacks

- Streamlines sequencing, protects the structure, keeps project moving

- Saves time, labor, and expensive project setbacks

Green, Fresh Pour Structural Concrete

Install SlopeShield Plus SA over green concrete a minimum of 5 days after pour. Ensure the surface is dry to the touch and meets all the required preparation requirements published in the installation instructions.

| Construct | Pour | Protect Roof Deck |

| Structural concrete roof preparation | Minimum 5-day cure time, apply SlopeShield Plus SA on day 6 or thereafter | Apply SlopeShield Plus SA to partially cured concrete, interior trades can begin |

Lightweight Insulating Concrete

SlopeShield Plus SA can be applied to lightweight insulating concrete. Substrate preparation includes priming the surface with sodium silicate approximately two days after the pour to lock in free lime and stabilize the surface chemistry.

| Construct | Pour/Prepare | Protect Roof Deck |

|

Lightweight concrete roof preparation |

Minimum 5-day cure time, prime within two days, apply SlopeShield Plus SA on day 6 or thereafter |

Apply SlopeShield Plus SA to partially cured concrete, interior trades can begin |

Advantages of SlopeShield Plus SA Over Concrete

|

|

|

Applying SlopeShield Plus SA on day-6 of the cure process:

|

Upon full cure, 28 to 35 days, SlopeShield Plus SA creates a walkable surface with excellent traction and supports construction equipment |

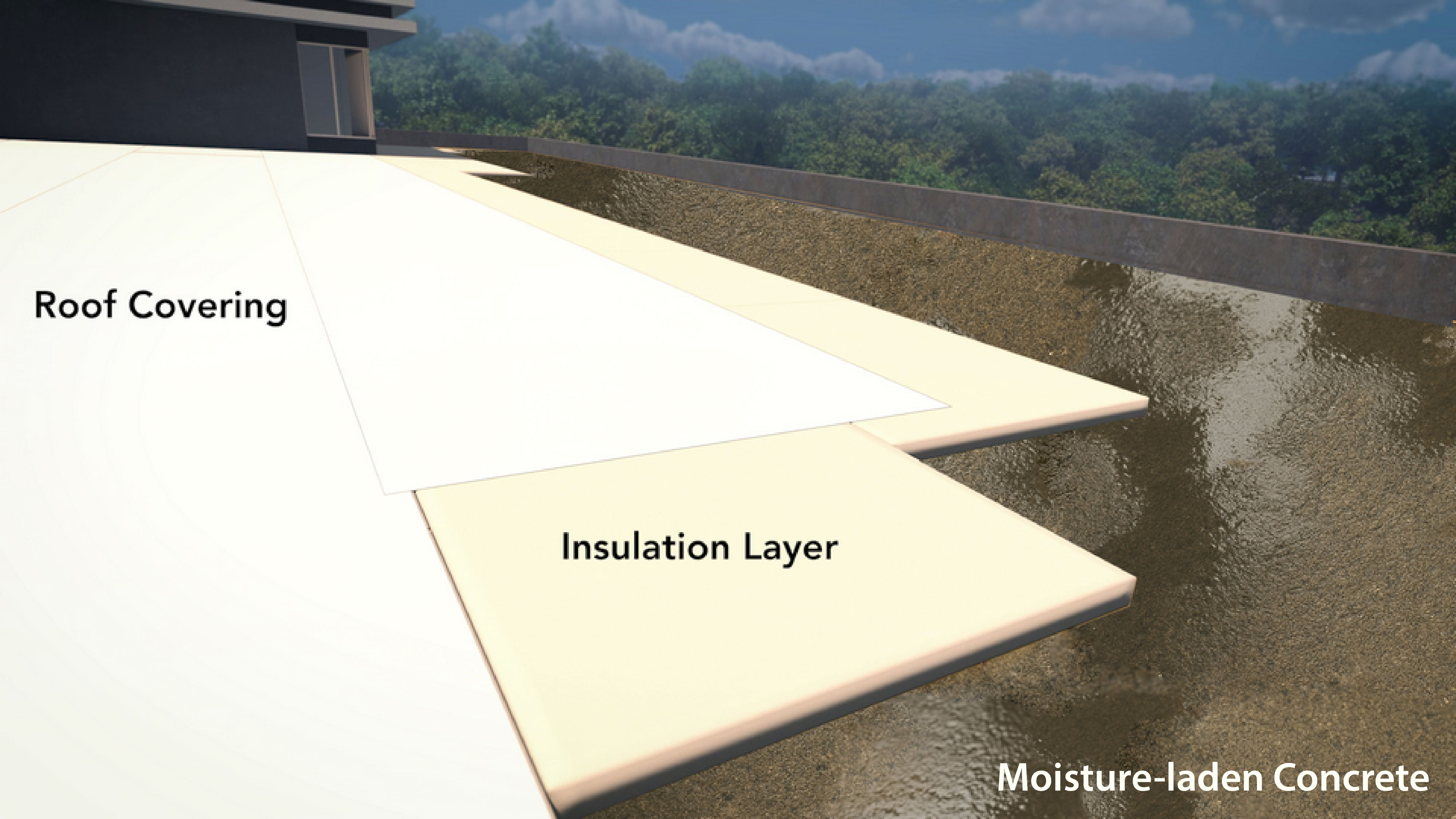

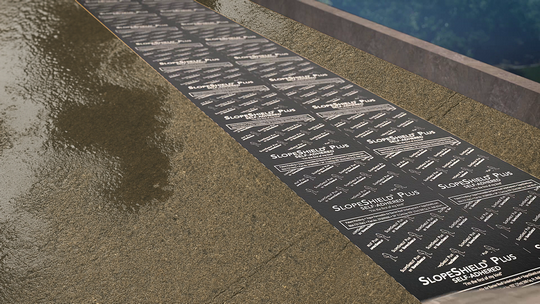

Reroof: Damp Concrete

During reroofing, damp concrete is often uncovered, causing delays while it dries. Applying SlopeShield Plus SA eliminates rewetting—even after rain—reducing schedule uncertainty and maintaining interior operations.

| Remove | Protect | Remain Operational |

|

|

|

|

|

Damp concrete is exposed |

Apply SlopeShield Plus SA to damp concrete |

Concurrent drying and protection maintains project momentum |

Cure Times and Installation Guidance

SlopeShield Plus SA does not accelerate the natural curing process of concrete; proper curing is still essential for substrate integrity and performance. While SlopeShield Plus SA protects the concrete from external moisture and allows internal vapor to escape, VaproShield recommends allowing 28 to 35 days of curing from the pour date before installing the final roofing system. This guideline aligns with industry standards to ensure optimal results.

| Continue the Conversation With Us |

|

Concrete Roof Deck Protection Resources

Related Products

August 26, 2024

| Property | Test Method | 2022 Standard (14 Tests) |

| Air Permeance | ASTM E2178 | |

| Apparent Core Density | ASTM D1622 | |

| Compressive Strength | ASTM D1621 | |

| Dimensional Stability at 28 days | ASTM D2126 | |

| Fungi Resistance | ASTM C1338 | |

| Gap Bridging - Declare gap width and temperature tested | ABAA 0004 | |

| Open Cell Content, Volume | ASTM D6226 | |

| Pull Adhesion | ABAA 0002 | |

| Surface Burning Characteristics | ASTM E84 | |

| Tensile Strength | ASTM D1623 | |

| Thermal Resistance for a 25-mm thick specimen | ASTM C518 | |

| Water Absorption by Volume | ASTM D2842 | |

| Water Resistance with a 55-cm head of water | AATCC 127 | |

| Water Vapor Transmission Rate for a 50-mm thick specimen - water and desiccant method | ASTM E96 |